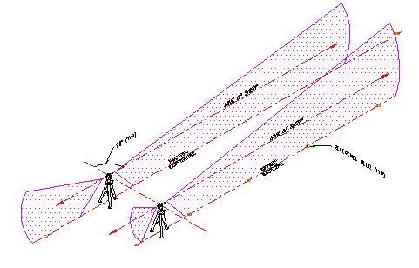

The illustration depicts the ?optical planes? that are established before installation of new machinery. Once the initial centerline has been installed based on blueprint requirements, an optical ?line of sight? (LOS) is established. From this LOS, additional optical planes are established relative to the original centerline.