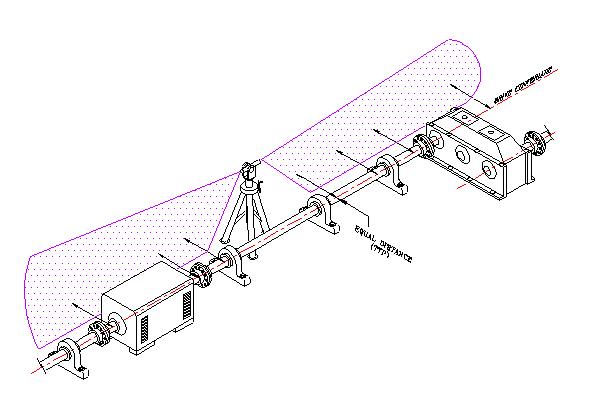

As you can see, optical alignment, as applied to drive systems, can compare centerline offsets and straightness within thousandths of an inch due to its measuring abilities. Because optics provides a flat and straight plane over long distances, horizontal and vertical adjustments may be accomplished to minimize offset alignment and virtually eliminate angular misalignment at couplings.