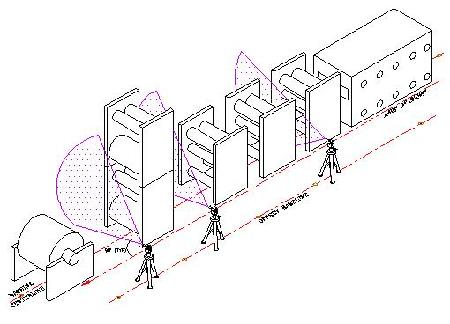

Optical planes are established 90 degrees from the reference. Individual components can be inspected for their square position using this 90-degree plane. Optical alignment equipment should be capable of producing this 90-degree angle within one arc second, which calculates to approximately .001″ deviation in 17 feet. Overall, roll alignment may be less then .001″ per foot of roll width if not specified by the manufacturer.